ABOUT US

PEBS is a project of Ittefaq Group that provides a complete end to end solution, from concept and design to the actual delivery of the building. Our engineers plan projects in the most economical, energy efficient and sustainable ways possible.

Pre-Engineered Building Solutions

Imagine calling ONE Company that provides an end-to-end solution from concept and design to the execution and delivery of the building. Yes, that company is PEBS (by Ittefaq).

PEBS by Ittefaq Group has a vast experience and one of the most technologically advanced facilities that helps conceptualise, design and deliver your next project!

Get a Quote For Your Project

WHY CHOOSE PEB?

Cost Effective

Time Saving

Portable

Energy Efficient

Earthquake Resistant

Eco Friendly

Light Weight

Durable

WHY CHOOSE US?

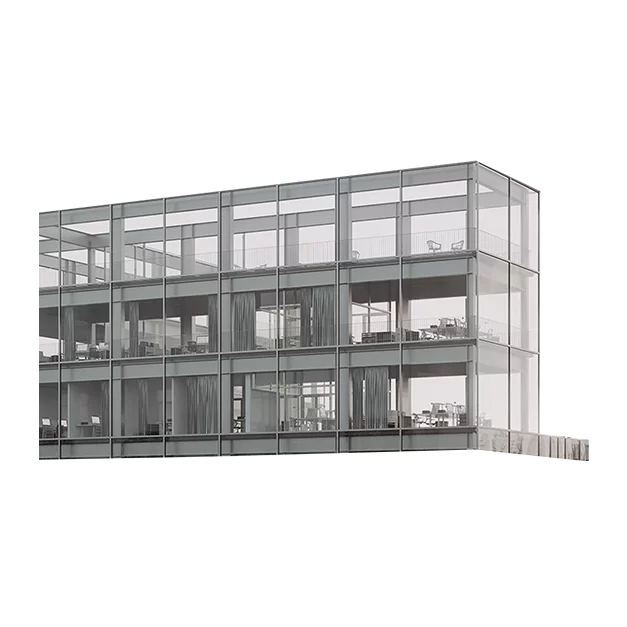

PEBS by Ittefaq group separates itself from its competitors in the market by not only providing solution-oriented plans that become aesthetically pleasing buildings, but by its remarkable team and after sale services, on top of which our structures are planned in such a way that keep costs low in the short and the long run. Being a part of the Ittefaq group of companies PEBS provides every service imaginable whilst constructing a commercial building, such as the provision of solar panels, BTD, MEP, Firefighting Service Lines and much more. We pride ourselves on the usage of technologically advance softwares and our strict code of conduct following international standards. So, if you’re interested in the details of how we work, give us a call or visit us in person, our teams would love to share more.

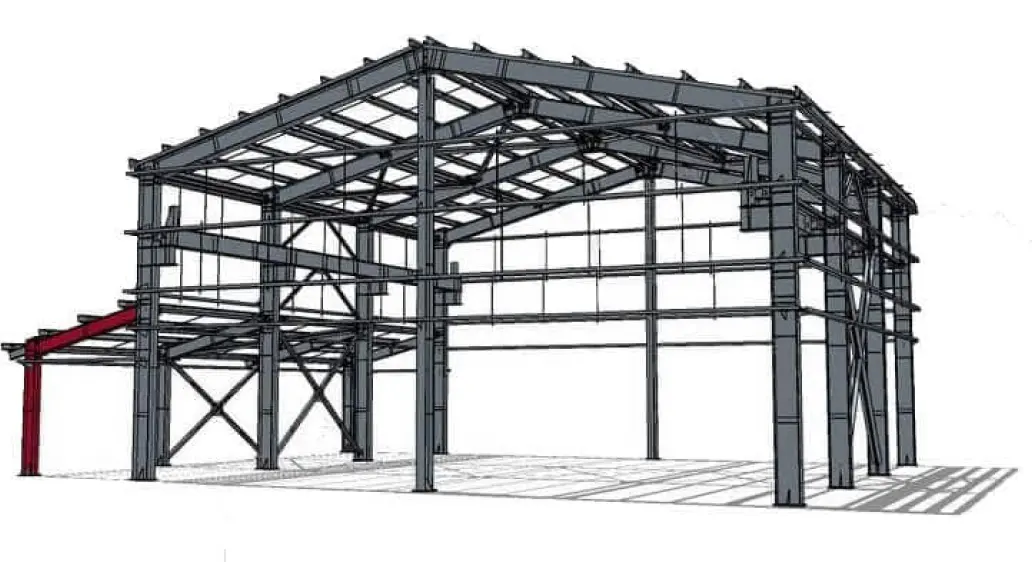

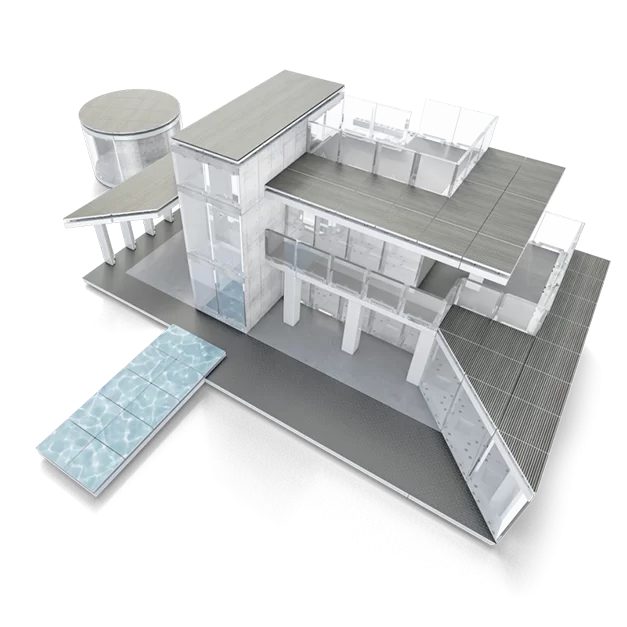

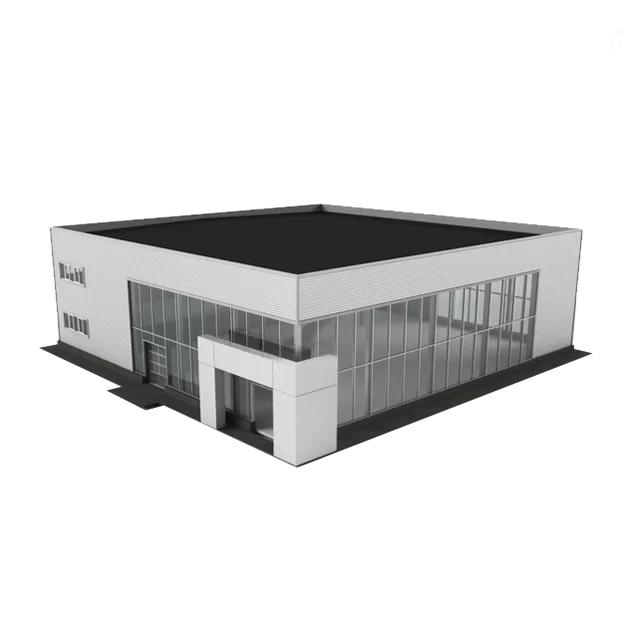

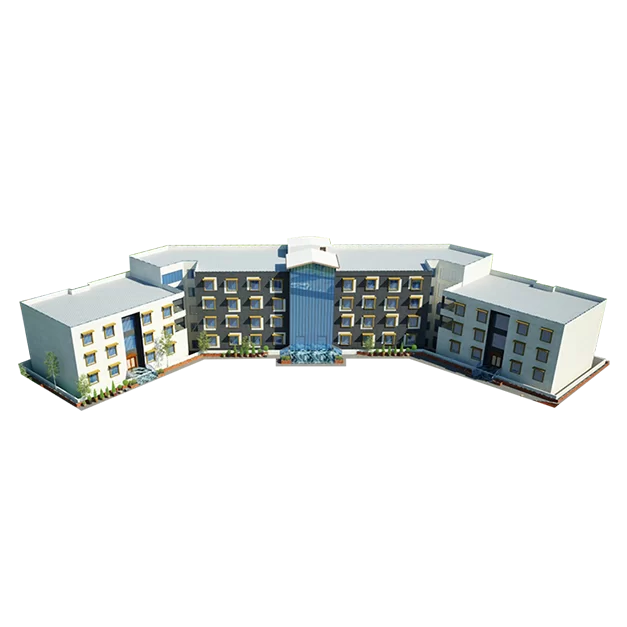

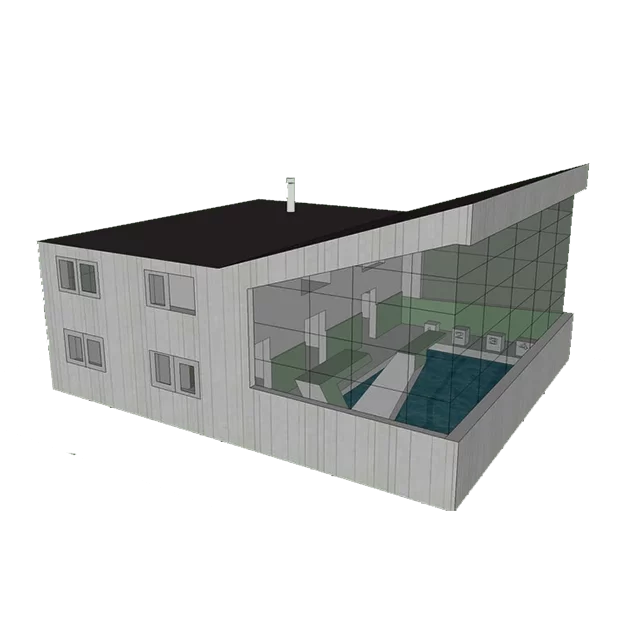

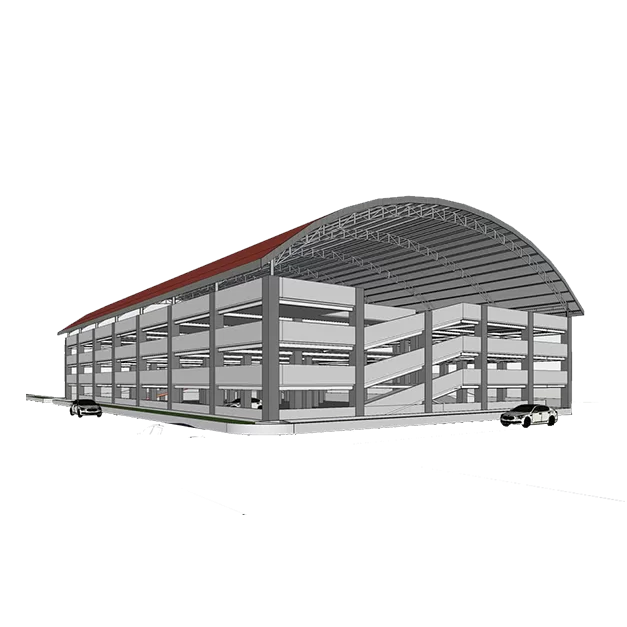

APPLICATIONS

Here are just a few APPLICATIONS of where you can apply Pre-Fabricatied Building solutions. It doesn’t necessarily need to be this, it could be anything that you’ve imagined for your upcoming project. Our team can develop custom designs that suit your usage & functionality whilst keeping it a BUDGET FRIENDLY SOLUTION

Production unit

Mall

Warehouse

Multi story building

Showroom

School Buildings

Community Center

Car Parking

OUR PROJECTS

CODES & SOFTWARES

Pre-Engineered Buildings That Last a Lifetime

OUR CLIENTS